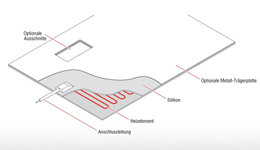

Isopad silicone panels are fully waterproof and suitable for applications up to 200°C. Formed by encapsulating a resistive heating element between two layers of semi vulcanised silicone rubber and then sealed under temperature and an even pressure to form a single vulcanised silicone sheet.

Uniform heat density is achieved using decades of experience at the design stage and the heating element is precisely laid using a numerically controlled 2 axis positioning system.

Isopad silicone panels use no adhesive and as they are essentially a single piece of silicone and there is no seam which is a common failure mechanism in panels manufactured using lower quality methods.

Isopad silicone panels provide good resistance to ozone, oxygen, weathering, ageing effects, bacterial and fungal attacks. They are also highly resistant to various chemicals such as alcohol, acetylene, mineral oil, acids, glucose, and glues. Isopad silicone heating panels can also be toughened with glass cloth when improved mechanical strength is required.

Glass silk heating panel (450 °C)

A highly flexible and versatile panel suitable for applications up to 450°C and produced by encapsulating a resistive heating element in glass silk. Isopad offer this product with several fixing methods from hooks and eyes, to lace, to Velcro depending on the client’s specific needs.

Quartz cloth heating panel (900 °C)

Identical to the glass silk heating panel from a construction perspective the maximum operationtemperature is increased from 450°C to 900°C by changing the insulation material to quartz cloth.

Metal cased heating panel (1000 °C)

At the core of an Isopad metal cased heating panel lies an MI heating cable which results in an inherently robust product. The MI element is precisely formed to achieve a uniform heat densityand fixed to a metallic plate for use as a radiant or contact heater. Isopad metal cased heating panels are ideally suited for use in high vacuum applications where it is essential to address thepotential failure mechanisms at the design stage.Minimum number of vacuum feed-throughs THERMOCOAX has access to the longest lengths of mineralinsulated cable in the industry and therefore a minimum number of feed-throughs and cold-lead joints is possible.High temperature, reliable cold-lead joints Isopad cold-lead joints are laser welded which, not only increases the operation temperature compared to brazed joints, but also greatly improves the reliability of the joint.Avoid introducing possible sources of volatile contamination The all-metal construction is very suitable for use in high vacuum equipment as it prevents contamination from volatiles. Vacuum feed-throughs and sensors are supplied as part of the assembly to remove the risk of contamination

prior to installation.

Radiant heaters

Where heat transfer through physical contact is not possible or desirable, an Isopad radiant heater is the ideal solution. It combines the uniform heat density and robust properties of a

mineral insulated heating cable with a highly polished, support plate. Directed heat with a withstand temperature up to 1000°C is possible and panels can be manufactured up to 5 square

meters.

Platen heaters

Isopad platen heaters are produced by mounting a mineral insulated cable within an aluminium plate which has been machined to exacting tolerances and controls. Typically weighing up to 500 kilos and measuring up to 5 square meters Isopad supply some of the largest heating platens in the industry.