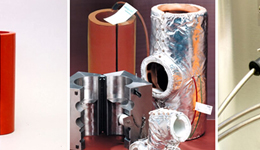

Heating Jackets

sopad heating jackets provide a convenient solution blending the versatility of a heating panel with the convenience of integral insulation. A heating panel excels when it is required to heat a flat surface, where a jacket is the product of choice when a uniform heat source is required to a surface in more than 2 planes, for example pipes, filter housings, valves and tees.

A distinct advantage is maintenance down-time; it is significantly quicker to remove a jacket with integral insulation than it is with other heating methods such as a heating tape with sensor, lagging and securing tape.

Isopad heating jackets can be manufactured to almost any shape, temperature range and operational

consideration.

Technology

Silicone jackets (200 °C)

Isopad silicone jackets are fully waterproof and suitable for applications up to 200°C. At the core lies an Isopad silicone panel, insulated with silicone foam and fully encapsulated is silicone rubber.

There is often no need for mechanical fixing as the Isopad silicone jacket is flexible enough to open and position on to the product to be heated but rigid enough to hold itself in position.

Uniform heat density is achieved using decades of experience at the design stage and then the heating element is laid using a numerically controlled 2 axis positioning system.

Isopad silicone jackets provide good resistance to ozone, oxygen, weathering, ageing effects, bacterial and fungal attacks. They are also highly resistant to various chemicals such as alcohol, acetylene, mineral oil, acids, glucose and glues. Isopad silicone heating panels can also be toughened with glass cloth when improved mechanical strength is required.

|