|

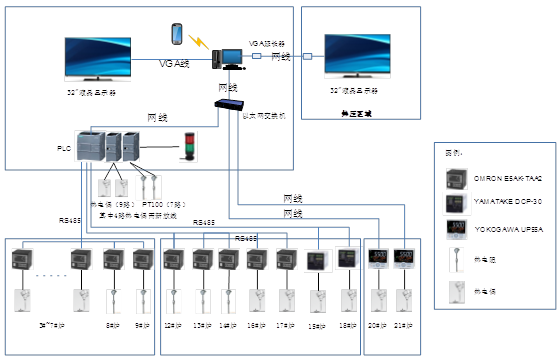

As an integral part of Industry 4.0 project of a famous global plastic manufacturing company,the supervisory system of oven line helps the client to improve the operation efficiency and prevent quality failure.

The system consists of PLC data acquisition, visualization software, Kanban. Operation and maintenance person easily get the running state of the equipment at the first time,and the system also provides a reliable means for the processdata analysis and helps to improve process parameters.

System overview

The system consists of three process areas with a total of 16 oven equipments, having the following functions:

-

Oven status display

-

Real-time temperature curve

-

Historical temperature curve

-

Real time alarm display and log

-

History alarm and event query

-

Oven program alarm setting

-

Automatic alarm phone cal

|